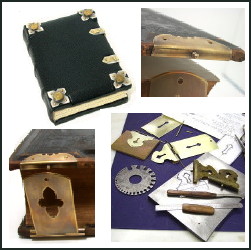

In the Beginning: Clasp I

Clasp I: Originally posted 2003 on bookclasp.com.

The original challenge was to create clasps which could also be made easily by those with minimal jewelry or metal working skills. This necessitated using a limited range of easily available tools.

In my research I found an article by J. Franklin Mowery.“Clasps, Schliessen, Clauseren: A guide to the manufacture and the literature of clasps.”Guild of Bookworkers Journal, Volume XXIX, No 2, Fall 1991. Copies available from the Guild of Bookworkers, 521 5th Ave., New York, NY 10175.

Using that as an initial guide, and drawing from my 25 years experience as a metalsmith, I proceeded to make some model clasps.

This first clasp was made using a small piece of 22 gauge brass strip. Metal files were used for shaping this pattern. Various metal stamps were used to decorate the top of the clasp. Then a nibbling tool was used to make a parallel slot and the knuckles for the hinge and catch mechanism were rolled around a pair of round nosed pliers.

Brass escutcheon pins were modified and used for the rod which spans the clasp catch and for riveting clasps to the boards. Escutcheon pins were also used to attach and secure hinge mechanism.

Once the clasps were attached to the book boards, the hasp length was estimated and trimmed. Proper final fit of the catch mechanism was determined by trial and error. Then the strap, or hasp, made of 22 gauge brass, was curled very slightly until it just clipped over the bar on the top catch plate.

When correctly made and fitted, the swell of the book creates enough tension to hold it closed, and simply pressing on the top of the book board will release the clasp.